ULMA facade at the Museum MIS, Rio de Janeiro

ULMA Architectural Solutions has successfully tackled a very special project that has pushed its abilities to the limit. This is an important project, where the level of customisation and the adjustments made at all levels have been highly demanding.

Its ability to adapt to different needs was key to the success of one of its most demanding projects:

The manufacture and installation of the west facade of the new Museum of Image and Sound in Rio de Janeiro (MIS/RJ), which, with a composition of more than 100,000 engineered stone panels, portrays the face of Carmen Miranda.

The new headquarters of MIS/RJ has been designed by the award-winning New York based interdisciplinary design studio Diller Scofidio + Renfro. The development was carried out by the Brazilian studio Indio da Costa - AUDT.

The project, the result of an international tender held in 2009, was conceived as an extension of the distinctive beach promenade designed by Roberto Burle Marx. streched vertically into a museum.

The new MIS/RJ, an initiative of the government of Rio de Janeiro and the Roberto Marinho Foundation, will house the entire collection of the museum, which opened in 1965 and is currently split between two buildings. The museum will have galleries, educational and leisure areas, as well as a space for the Carmen Miranda Museum (which will replace the current one, located in Flamengo Park).

In honour of the Portuguese-Brazilian singer and actress, the west façade received a three-dimensional mural which, due to its geometry, scale and diversity of colours, allows the public to see the artist's eyes or smile, depending on where they are located.

The executive project initially planned the use of precast ceramic-tiled concrete elements. However, as the architect Indio da Costa explains, the ULMA ventilated facade system offered a better technical response, besides providing speed and efficiency in production and installation, key factors for the success of the work.

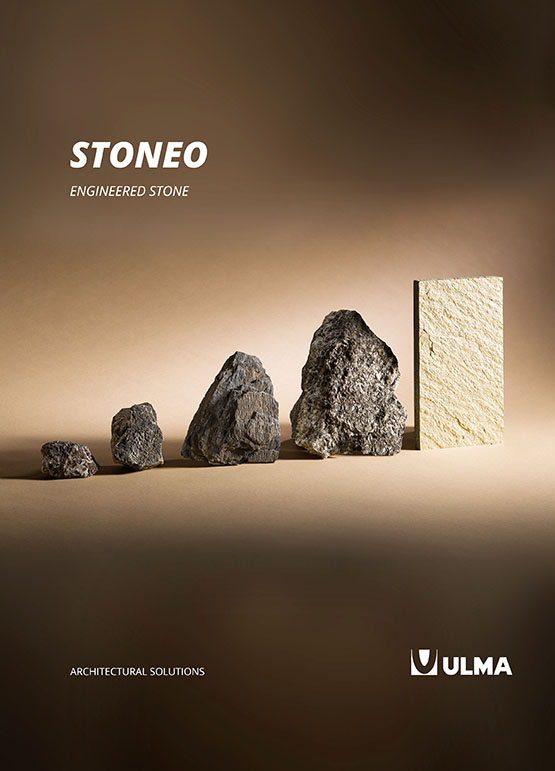

To meet the high level of customisation required by this proposal, the Stoneo Art line was used, enabling the manufacture of 100,000 15 x 15cm panels, in six shades of grey. According to ULMA, each panel acts like an independent pixel, allowing different images to be formed by simply changing the colour of each piece.

"One of ULMA's advantages, compared to other manufacturers, is that it can manipulate the digital files in order to allow the direct conversion between the digital image provided by the architects and the manufacturing and the physical mapping of modular elements" the owner of Indio da Costa AUDT studio highlighted.

Polymer concrete comes from a combination of silica and quartz, bound by polyester resin, and it is resistant to saline environments and anti-graffiti treatment, besides allowing the customisation of colours and textures.

"This was a very important factor, because the mural art consists of 'black and white' images, or which require a gradual and consistent relationship between the shades" Indio da Costa stated.

Another advantage is it has a Leed certification rating, as it guarantees better thermal insulation and greater energy savings.

"We were impressed by the fact that the system is 100% prefabricated, unified and dry mounted. This provides absolute precision, in response to the need for perfect vertical and horizontal alignment. Moreover, the manufacturing instruments perform precise cutting of the panels with mitre, allowing the coloured pieces to fit into the corner without seeing the thickness of the material.The samples prepared on the ceramic tile offered a poor and unsatisfactory corner finish" according to the architect.

The installation of the facade, covering 2,300 square metres, required ULMA's technical team to perform a rigorous quality control, which was carried out in all areas, including manufacturing, cutting, sorting, packaging and shipping the panels separated into batches by area of application, ending with one of the most complex parts: installing the panels. Therefore, they were later fitted into aluminium substructures attached to the concrete wall at an angle of 90 degrees.

As Javier de Iribas, Director of Ventilated Facades pointed out “It is the most demanding challenge we have faced in our entire history in the world of ventilated facades. This project has stretched all our capabilities to the limit; manufacturing, architectural, and even engineering. A comprehensive solution based on our most creative and customisable range, the Stoneo Art Range. For this, a multidisciplinary team worked closely with DS+R to realize their bold design vision for their museum. Primary and secondary substructure systems adapted to a panel format of minimum dimensions, machined with mitre joints specific for arrangement on the façade in the shape of a sawtooth, and exclusive handling and packaging for more than 100,000 panels that make up this wonderful pixel pattern of 6 non-standard colours that have contributed, after flawless execution, to clearly reflecting the spectacular image of Carmen Miranda. In short, a project that has made us grow as a company and that will project us with guarantees, and without a doubt, to new and more demanding future challenges”.

By distributing the loads on the building's structural elements, the ventilated facade is extremely lightweight and safe.

It was a very special project that was very demanding and the result has left its creators 100% satisfied. Chris Andreacola Project Leader at the NY Studio Diller Scofidio+ Renfro stated: “We did not find one single pixel/panel out of place, and not only that, we were pleasantly surprised with the final result of the work, as it has exceeded all our expectations”.