Polymer concrete

Polymer concrete is a high quality material composed of a select combination of aggregates.

The optimal mixture, bound using polymeric resins, passes rigorous quality controls and results in 4 times greater strength than traditional concrete. This allows us to considerably reduce the section of the prefabricated material, meaning we can produce lightweight elements with small dimensions.

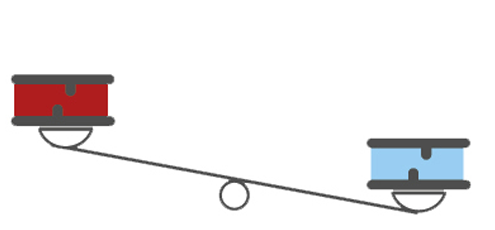

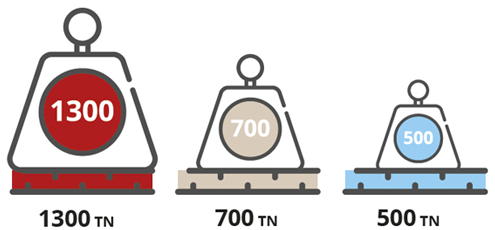

Compressive strength

Applied to prefabricated systems, it can support up to 1300 kp/cm2 compared to the 700 kp/cm2 supported by fibre cement or 500 kp/cm2 supported by traditional concrete. Before breaking or cracking!

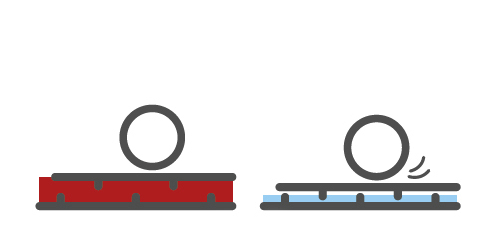

Abrasion resistance

The hardness of the silica aggregates guarantees good conservation of surfaces exposed to road traffic.

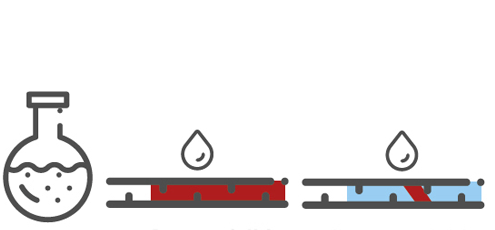

Resistance to chemicals

One of the most resistant materials to any chemical product. Its components do not react to contact and prevent disintegration and deformation. Proven! Optimal abrasion resistance!

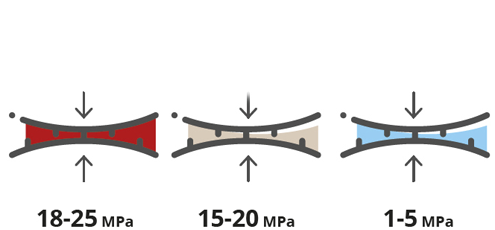

Flexural strength

Applied to prefabricated systems, it can support up to 18-25 MPa compared to the 15-20 supported by fibre cement or the 1-5 MPa2 supported by traditional concrete. Before breaking or cracking!

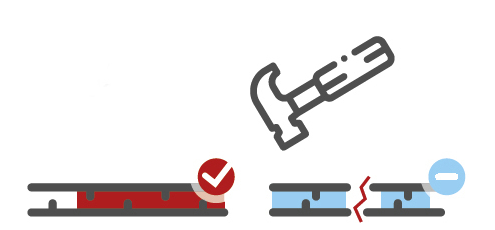

Shock resistant

As it is a composite material, it guarantees the perfect conservation of surfaces against usage or the passing of time. No perception of wear!

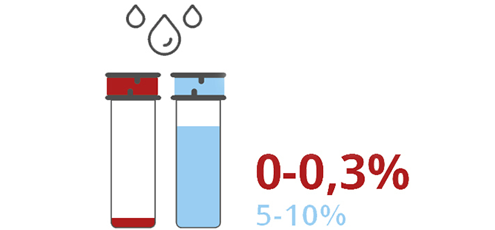

Zero water absorption

It has practically 0% water absorption and guarantees the sealing of the pieces. Impermeable!

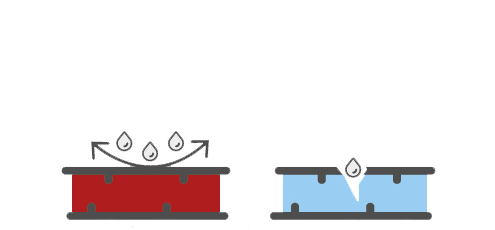

Unalterable in freeze/thaw cycles

On the contrary to traditional materials it is not affected by freeze-thaw cycles and prevents the appearance of fissures or cracks. It maintains all properties intact!