Trench Drains for Public Projects: Efficient Drainage Solutions in the USA

Effective surface water management is essential for building resilient public infrastructure across the USA. From urban roadways to airports and freight terminals, heavy duty trench drain systems play a critical role in protecting assets, improving safety, and optimizing long-term performance.

Why Trench Drains Are Essential for Public Infrastructure

Public projects such as highways, ports, and airports are exposed to intense traffic loads, harsh weather, and chemical agents. Heavy-duty trench drains are engineered to handle these challenges by efficiently capturing surface runoff, resisting corrosion, and ensuring long-term durability.

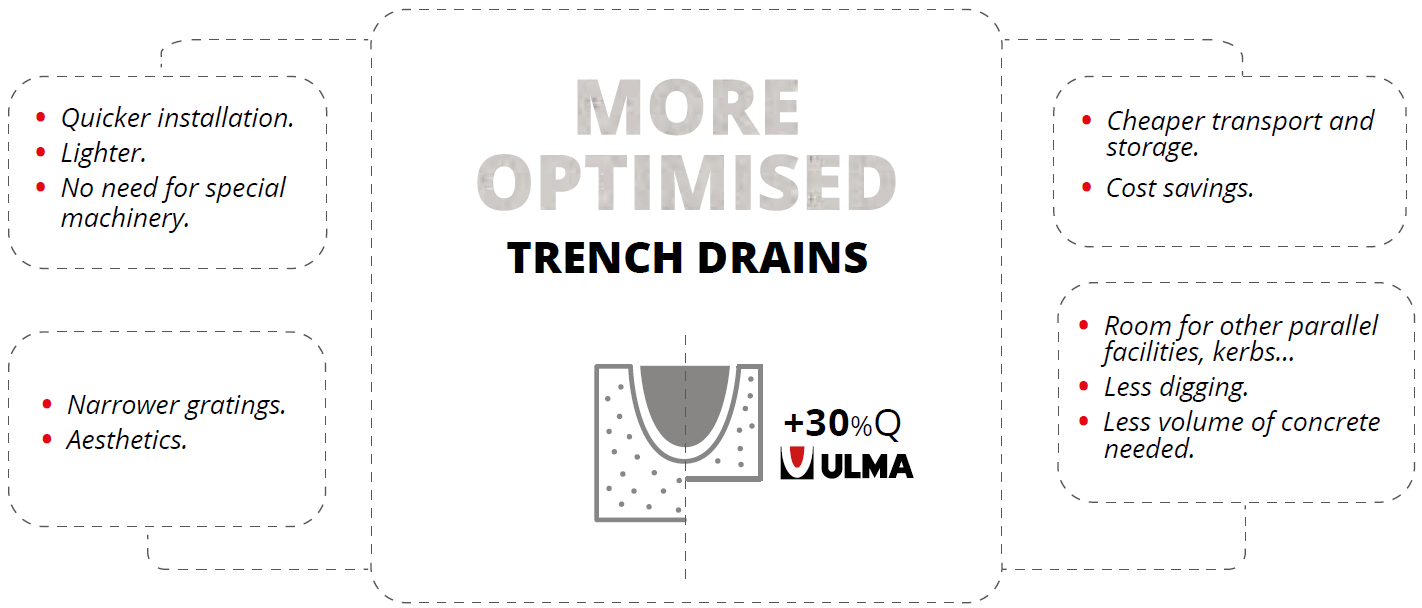

The Advantages of Polymer Concrete Trench Drain Systems

ULMA’s trench drain systems are manufactured using high-performance polymer concrete, offering key advantages for public infrastructure:

- High strength-to-weight ratio, allowing faster and safer installation on site

- Excellent resistance to chemicals, de-icing salts, and freeze-thaw cycles

- Minimal water absorption, reducing the risk of cracking and structural degradation

- Long-term performance with low maintenance, even in high-traffic environments

- ADA Compliant: Designed to meet Americans with Disabilities Act (2010) Section 302.3, ensuring safe and accessible pedestrian surfaces

Whether you're designing a drainage trench for an airport, a channel drain for a highway, or a trench drainage system for urban roads, ULMA delivers performance, reliability, and regulatory compliance.

Key Applications: Roads, Parking Areas, and Urban Spaces

Trench drains are used in a wide range of settings:

- Roads and highways: Reduce hydroplaning and extend pavement life.

- Airports and ports: Manage heavy traffic and large surface areas.

- Parking lots and commercial centers: Improve runoff control and pedestrian safety.

Channel Drain vs. Traditional Trench for Drainage: What to Choose?

Compared to traditional systems, ULMA’s trench drain channels deliver an optimized hydraulic capacity, structural performance, and installation speed. Our polymer concrete systems are also lighter and easier to handle than cast-in-place concrete.

Case Studies: Trench Drain Installations Worldwide

ULMA’s KompaqDrain®-CIVIL 150 polymer concrete channels, equipped with the advanced MAX-FLOW® system, were installed to ensure maximum drainage efficiency in this major tunnel infrastructure project. These monolithic trench drain systems offer Class F900 load resistance, making them ideal for heavy-duty environments subject to high vehicular pressure and frequent water runoff. The tunnel, a cornerstone of London’s public infrastructure expansion, required a drainage solution that would perform reliably under long-term mechanical and environmental stress.

2. Northampton Service Station and Lorry Park

Persistent surface water problems led to the installation of 820 linear feet of Civil-F trench drain channels (model F150K), paired with F900 rated gratings. This heavy-duty trench drain system drastically improved surface water management, boosted safety, and helped reduce overall maintenance costs. The location’s continuous lorry traffic and exposure to oil and de-icing chemicals made polymer concrete an ideal choice for resilience and performance.

3. Costco Walmart Fuel Station, Spain

Across multiple refueling stations for large vehicles, ULMA installed Civil S250F and SM200F polymer concrete trench drain channels (F900 Load Class). These driveway trench drains were engineered to withstand frequent heavy-duty loads and resist chemical degradation from fuels, lubricants, and cleaning agents. The project highlights ULMA’s expertise in providing custom drainage systems for demanding logistics hubs.

As the largest airport in Latin America, Guarulhos handles more than 39 million passengers annually. For this high-traffic site, ULMA supplied 10,500 linear feet of heavy-duty trench drain channels—models F150K and F300K—fitted with ductile cast iron gratings. These drainage systems are positioned in areas subjected to extreme axial loads due to taxiing, maneuvering, and braking of aircraft, ensuring long-term durability and operational safety.

5. Castillon Tunnel, France

In this confined tunnel setting, ULMA installed KompaqDrain® 100 City—compact, monolithic trench drain systems optimized for tight installation environments. With their all-in-one design and high flow efficiency, these drainage channels are ideal for applications requiring minimal installation depth and high resistance to continuous vehicular traffic.

Connecting São Paulo to the Port of Santos, the Anchieta Motorway is one of the busiest roadways in Brazil. To accommodate site-specific drainage needs, ULMA provided 9,840 linear feet of KompaqDrain® Traffic trench drain systems in three different heights. These polymer concrete channels were designed to deliver effective water evacuation in an area prone to intense rainfall and heavy freight movement.

Selecting the Right Trench Drain System for High-Traffic Areas

Choosing the best trench drain system for large-scale civil projects requires a close look at load capacity, hydraulic performance, durability, and site-specific constraints. ULMA provides a comprehensive range of heavy duty trench drain solutions engineered for demanding environments:

- Civil-F Series: These F900 drainage channels are designed for areas exposed to extreme mechanical stress, such as highways, airports, and logistics hubs. They offer robust structural integrity and long-term performance under continuous traffic loads.

- Civil-S Series: A shallow yet heavy duty trench drain system, perfect for confined installations like refueling stations, port facilities, and industrial zones. Despite their lower profile, they still support load classes up to F900, combining strength with flexibility.

- KompaqDrain® Series: A monolithic channel drain solution with integrated grate, providing excellent resistance to deformation and maximizing flow with ULMA’s exclusive Max-Flow® technology. Ideal for trench drainage in high-traffic areas where safety and efficiency are critical.

Each trench drainage system is manufactured from polymer concrete, offering high chemical resistance, low water absorption, and lightweight installation advantages.

ULMA’s Engineering Office is ready to support your design process—offering layout guidance, hydraulic analysis, and documentation to ensure your system meets both project specifications and U.S. regulatory standards.